Dairy Production Industry: Exploring Innovative R&D

The dairy industry has long changed from its romantic roots of a farmer getting up at dawn and hand-milking the entire herd. Science has stepped up in a big way and now dairy production is shaped by science and technology.

The article delves into the latest techniques in dairy production, focusing on the use of artificial intelligence and machine learning to enhance efficiency.

Dairy Production Advancement #1: Precision Farming

Precision farming in dairy production involves using technologies to monitor an animal’s behavior, physiology, and production indicators. By attaching or implanting sensors, farmers can wirelessly transmit data about milk yield and quality, and compare individual animal output against the herd to optimize feeding and milking systems for increased efficiency and productivity.

In a 2019 study published by Cambridge University Press in the journal “animal,” researchers examined the repeatability of feed intake patterns in dairy goats and identified the variables with the greatest impact. They observed 35 dairy goats from Alpine or Saanen breeds, measuring their eating speeds, the percentage of food consumed immediately after delivery, and its effect on dairy output. The study revealed several significant findings:

- Alpine goats ate more slowly than Saanen goats.

- Alpine goats spread out their eating over a longer duration than Saanen goats.

- Older goats sorted more against the fibrous part of the total mixed ration.

- Older goats had a higher rate of intake than younger goats.

They learned, through phenotyping and precision farming, how, when, and how long to feed goats to increase feed efficiency and keep them healthy by limiting the occurrence of acidosis.

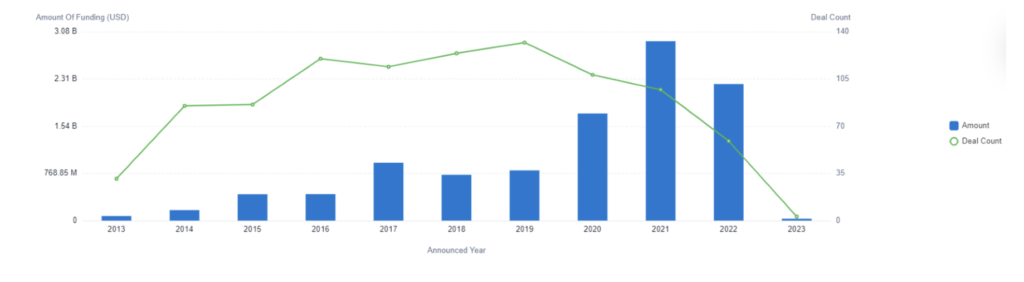

As the chart above illustrates, in recent years VC investments in precision farming have surged. This indicates there is a growing focus on integrating this technology into agriculture practices.

Dairy Production Advancement #2: AI and Machine Learning

The implementation of AI and machine learning is transforming dairy production. The academic paper “The role of sensors, big data and machine learning in modern animal farming” published in Sensing and Bio-Sensing Research explores the many ways in which these technologies can improve animal health and productivity while reducing sickness and the spread of disease.

In the paper, the authors discussed how the biggest cost in animal farming is the number of animals grazing on a parcel of land for a specified time (stocking rate), followed by feed and disease management. Using AI and machine learning to form mechanistic models can help identify — and solve — problems related to the optimal nutrient composition of animal feed; assess animal management for their performance; and come up with ways to limit nutrient excretion into the environment.

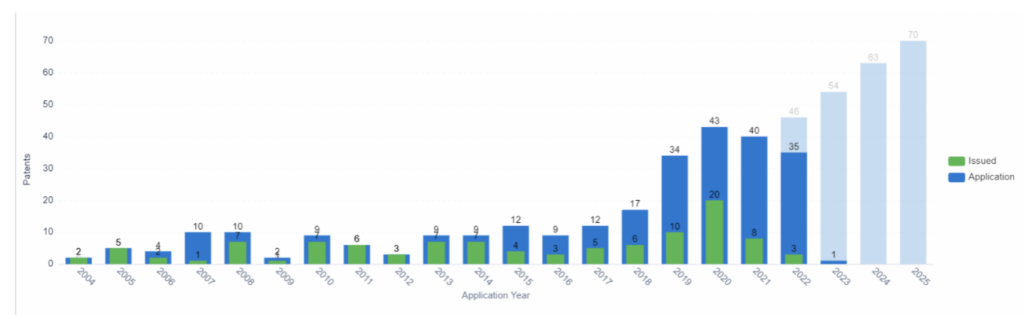

AI is becoming increasingly popular in dairy production, as depicted by the chart above. The trend forecast (light blue bar) indicates that patent applications are expected to continue to rise over the next three years.

Some of the AI and machine learning tools at the disposal of farmers include:

- Sensors, like cameras; vision or motion detectors; infrared thermal imaging; temperature sensors; RFID tags; accelerometers; microphones; and more.

- Functional processes that account for weather and climate changes; animal behaviors; feed and water dosage and usage; and weighing machines.

- Combining wearable and non-wearable sensors, and invasive and non-invasive sensors.

- Computers, cloud computing, and big data to track data and create predictive algorithms.

For example, with milk-producing animals, lameness is the third most important disease affecting farming by simultaneously reducing milk production and increasing the risk of injury. But AI and machine learning can be used to create algorithms that predict lameness based on body movement, such as tracking changes in locomotion, over-use of specific body parts, and less use in other body parts. By getting an early jump on lameness, farmers can mitigate financial losses that might otherwise be compounded without technological aid.

Dairy farmers can also become more proactive about the deleterious effect of diseases on their herds by monitoring health factors, like movement, air quality, and any changes in food and water consumption. Because contagious diseases can spread extremely rapidly in herds that spend prolonged time together, farmers can pre-emptively separate diseased animals from the rest of the herd before the disease runs rampant and leads to a large-scale outbreak.

Dairy Production Advancement #3: Genetic Engineering

Bovine mastitis, an inflammation of the mammary gland caused by trauma or infection, poses a significant financial burden to the dairy industry, especially with global prevalence of Staphylococcus aureus reaching up to 70.3% in dairy herds. Currently, antibiotics are the main treatment, but researchers in a published paper in Antibiotics explore more cost-effective methods, like genetic engineering, to address antimicrobial resistance to Staph. aureus.

These researchers evaluated molecular data from affected cows and found genetic similarities among strains. For example, in one cluster, cows affected by Staph. aureus were found to be more resistant to penicillin-based antimicrobials and less resistant to cephalothin as compared to the second cluster.

By analyzing the various biological sequences and molecular datasets of various pathogens, farmers can monitor transmission routes at the strain level and treat affected cows with the appropriate antimicrobial, which can promote healing and reduce resistance. For the more ambitious dairy farmers, they can selectively breed their dairy cattle to optimize genetic benefits and, hopefully, reduce the risk of bovine mastitis caused by Staph. aureus.

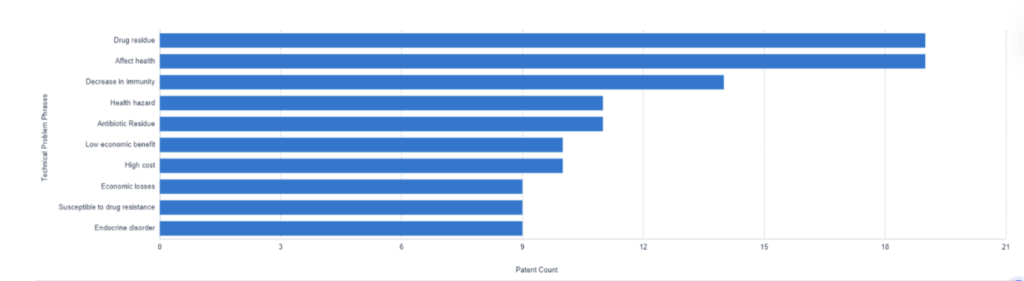

As the Eureka graph above shows, researchers are focusing on genetic engineering topics related primarily to drug resistance, health effects, and decreased immunity.

Dairy Production Advancement #4: Novel Processing Techniques

If you thought ultrasounds were reserved for humans, think again! A paper published in Ultrasonics Sonochemistry highlights the potential of high-intensity ultrasound (HIIS) as a preservative technology in dairy products, offering benefits such as shorter processing times, improved taste, reduced lactose content, and fewer ingredients.

Ultrasonography can also be used to treat pathogenic bacteria in dairy products, such as Listeria monocytogenes, which causes 23,150 sicknesses and 5,463 deaths per year. In a paper published in Trends in Food Science & Technology, researchers looked at how heat sterilization compared to other novel processing techniques, like high hydrostatic pressure or microwaves.

Although heat sterilization is commonly used in the food industry to safely produce, prepare, and store foods, it has several drawbacks: it can negatively impact the nutritional quality of foods, it changes the sensory properties, heat has a slow rate of penetration, it’s a time-consuming method, and most plastics will melt under the required heat for sterilization, necessitating costlier materials.

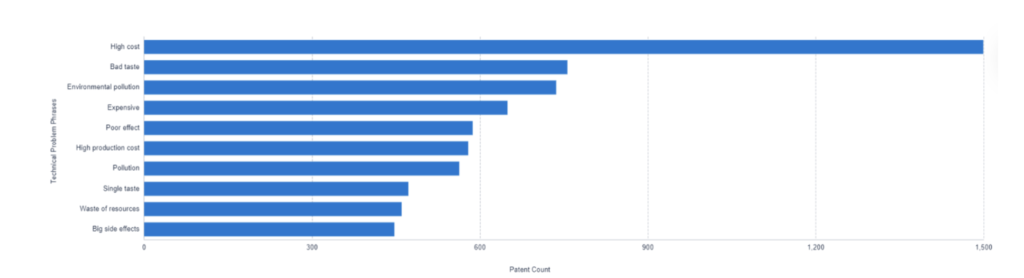

Researchers are actively seeking solutions to the issues of high cost, bad taste, and environmental impacts associated with milk treatments. As the chart above illustrates, patent applications focusing on cost reduction are a key area of research.

High hydrostatic pressure is one solution that can be used in either a single-pulsed or multi-pulsed method, with the latter more effective when it comes to inactivating microorganisms in dairy products and extending their shelf life. Microwaves and radiowaves are also used to treat milk, with microwave pasteurization resulting in less whey protein denaturation compared to heat. It’s also an effective method for reducing the risk of contamination from Listeria and Escherichia coli, two bacteria that can cause potentially severe illnesses.

Pros and Cons for Farmers

Dairy farming is not an easy profession, so farmers need to find a balancing act between work efficiency and quality product output. For example, using AI- and big data-driven sensors and technology can accurately and effectively predict costly illnesses in dairy herds, but the cost of equipment can be quite prohibitive. Additionally, there are other costs related to mastering and using the technology, storing it, and having the skills to both write and interpret the data.

Depending on the size of the dairy herd, a farmer may decide that such initial costs provide a valuable return on investment when compared to the costs of low product quality or a vastly reduced yield. As well, with these technologies, there is often a high initial investment that can be maintained more cheaply as time goes on, offering the opportunity to increase profit steadily year over year.

Ethical and Environmental Concerns

Along with farming pros and cons, there are also ethical and environmental concerns to consider. While used for product output, dairy cattle are still sentient beings and there exists a debate on the rights owed to them. If farmers genetically engineer their cattle to result in optimal creatures that are most resistant to bovine mastitis, what happens to the cows that don’t meet the threshold? And since genetic engineering is still in its relative infancy compared to other technologies that have been around for hundreds of years, do we fully understand the effects that genetic engineering can have on their bodies in the long term?

When it comes to environmental concerns, there are several matters to consider. While cloud computing and wearable technology can take up less physical space than older technologies, they still require a huge amount of energy and that impacts the environment, especially as the world is trying to become greener. And while AI and machine learning can result in larger herds that are more effective at producing dairy, those larger herds will produce more methane, which has a negative impact on climate change.

Closing Thoughts

Incorporating AI and machine learning in dairy farming has revolutionized the industry, enabling precision farming, efficient herd management, genetic engineering, and innovative processing techniques. These technologies not only promote dairy cattle health but also reduce operating costs and minimize loss expenses.

To fully reap the benefits, it’s crucial to utilize tools that save time, energy, and effort. With continued advancements and implementation of cutting-edge technology, the dairy industry is poised for even greater success in the future.

Interested in learning more about how PatSnap can help you innovate better? Check out our AI-powered platform, Eureka. It’s designed to make IP accessible for R&D professionals and accelerate innovation from concept to commercialization.